粉體行業(yè)在線展覽

粉體行業(yè)在線展覽

ETPC系列粉體輸送裝置

面議

廣州宇特

ETPC系列粉體輸送裝置

64

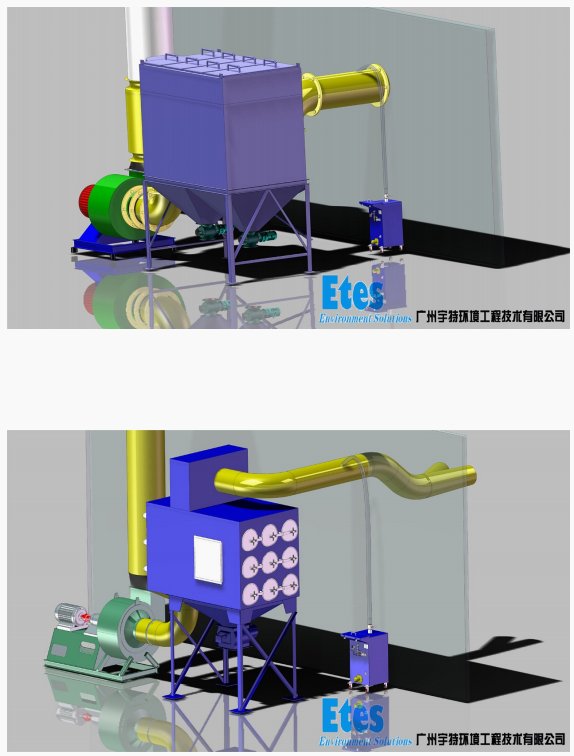

一. 工作原理 ETCP 系列粉體輸送裝置是除塵系統(tǒng)用于處理含油性粉塵、粘性粉塵防止糊袋及抑制粉塵燃爆的輔助 設(shè)備,該設(shè)備安裝于除塵器入口主管道處,系統(tǒng)工作時(shí)定時(shí)向管道中噴入石灰粉,依靠附著在濾材表面 的石灰粉層包裹塵氣中的油粒或粘性粉塵,達(dá)到易于清灰及抑制粉塵燃爆的目的。設(shè)備運(yùn)行穩(wěn)定(可 24 小連續(xù)工作),運(yùn)行成本低,操作簡單,設(shè)備體積小,管理維護(hù)方便,是您的理想選擇。在您準(zhǔn)備安裝 使用本產(chǎn)品之前,為了讓您安全正確的使用,請(qǐng)先仔細(xì)閱讀本說明書。

ETCP series powder conveying device is dust removal system used for treating of oily dust, sticky dust preventing paste and suppress the dust bums and auxiliary equipment, the equipment is installed on the collector inlet main pipe, the system work regularly to the pipeline into lime powder, rely on the attached on the surface of the filter material, lime powder dust layer surrounding the oil particles in the air or sticky dust, It is easy to remove dust and restrain dust explosion. The equipment runs stably (can work continuously 24 small), the operation cost is low, the operation is simple, the equipment volume is small, the management and maintenance is convenient, is your ideal choice. Before you prepare to install and use this product, please read this manual carefully for safe and correct use.

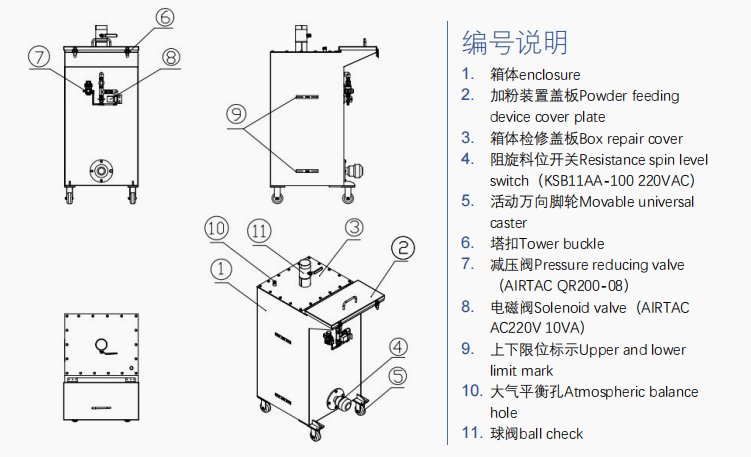

二. 設(shè)備的組成 ETCP 系列粉體輸送裝置裝置的主要組成部分:

ETCP series powder conveying device main components:

ETPC 系列粉體輸送裝置工作原理說明: ETPC series powder conveying device working principle description:

1:粉體輸送裝置是通過壓縮空氣作為動(dòng)力,將粉體輸送到除塵器內(nèi)部,起到保護(hù)濾材及仰然仰爆的作 用;

2:可以通過電控設(shè)置粉體輸送間隔及每次輸送粉體時(shí)間長短;

3:粉體輸送裝置可以通過旋阻料位 開關(guān)檢測箱體內(nèi)粉體量,達(dá)到下限位時(shí)機(jī)時(shí)輸出報(bào)警信號(hào)。

1: powder conveying device is through compressed air as the power, the powder is transported to the ball check5 inside of the dust collector, to protect the filter material and the role of inverted inverted explosion; 2: the powder conveying interval and the length of each conveying time can be set by electronic control; 3: powder conveying device can detect the amount of powder in the box through the spin resistance material level switch, and output alarm signal when reaching the lower limit.

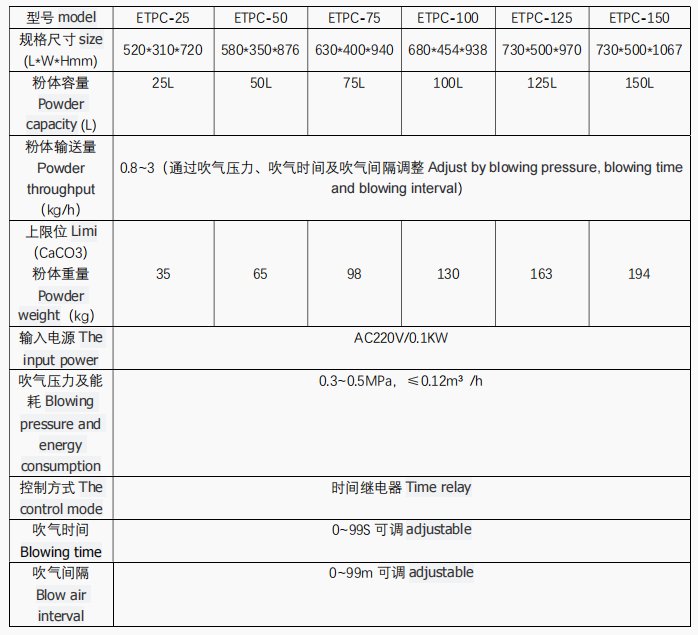

宇特 ETPC 系列粉體輸送裝置技術(shù)參數(shù)表

ETPC series powder conveying device technical parameters table

三、安裝注意事項(xiàng) Installation Precautions

3.1 設(shè)備安裝位于于需要防護(hù)的除塵設(shè)備之前的主管道側(cè)面或頂面處接入,接入角度不宜大于 45°,接口 距離除塵器入口應(yīng)大于 1 米;

3.1 The equipment shall be installed at the side or top of the main pipe before the dust removal equipment to be protected, the access Angle shall not be greater than 45°, and the interface distance from the dust collector entrance shall be greater than 1 meter;

3.2 粉體輸送裝置與管道系統(tǒng)之間的連接軟管應(yīng)垂直連接,防止軟管彎頭處出現(xiàn)粉體堵塞現(xiàn)象;

3.2 The connecting hose between the powder conveying device and the pipeline system should be vertically connected to prevent powder clogging at the hose elbow; 6

3.3 關(guān)閉設(shè)備電源總開關(guān),按照設(shè)備配置電壓,接好電源線后,再開啟設(shè)備電源總開關(guān);

3.3 Turn off the main power switch of the device and connect the power cable according to the configured voltage of the device before turning on the main power switch of the device;

3.4 壓縮空氣接入后需將壓力空氣調(diào)節(jié)過濾器壓力調(diào)節(jié)至 0.3~0.5Mpa 工作范圍;

3.4 After the compressed air is connected, the pressure of the pressure air conditioning filter shall be adjusted to the working range of 0.3 ~ 0.5mpa;

3.5 安裝在室外的設(shè)備要包好線頭,并做好防雨措施,杜絕漏電;

3.5 The equipment installed in the outdoor should be wrapped with wire ends, and do a good job of rain prevention measures, prevent electricity leakage;

3.6 在安裝本公司設(shè)備時(shí),請(qǐng)必須細(xì)心考慮有關(guān)電源(功率,電壓)配置,要有足夠的使用量。

3.6 When installing our equipment, please carefully consider the power supply (power, voltage) configuration, and ensure sufficient usage.

四、設(shè)備調(diào)試,使用說明 Equipment debugging, instructions

4.1 設(shè)備啟動(dòng): Device Startup: 安裝完畢后,開啟設(shè)備電源開關(guān),待綠色運(yùn)行指示燈亮后,設(shè)備即開始運(yùn)行。

After the installation, turn on the power switch of the device, and the device will start running when the green operation indicator is on.

4.2 啟動(dòng)流程: Start-up process: 氣源/電源開關(guān)-運(yùn)行開關(guān)-裝置啟動(dòng)-調(diào)節(jié)時(shí)間繼電器吹氣時(shí)間-吹氣-正常運(yùn)行。

air source/power switch - operation switch - device start - Regulating time relay blowing time - blowing - normal operation.

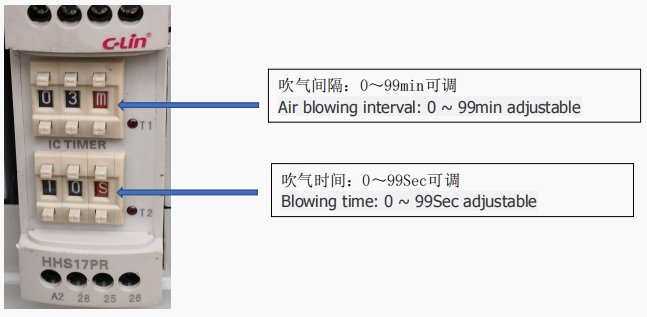

4.3 吹氣時(shí)間/吹氣間隔時(shí)間的調(diào)試: Debugging of blowing time/blowing interval time: 設(shè)備運(yùn)行啟動(dòng)正常后,根據(jù)現(xiàn)場實(shí)際情況,調(diào)節(jié)時(shí)間繼電器以得到相應(yīng)的吹氣時(shí)間及吹氣間隔時(shí)間,以 達(dá)到所需粉體輸送量大小的目的。

After the equipment runs normally, according to the actual situation on site, adjust the time relay to get the corresponding blowing time and blowing interval time, so as to achieve the purpose of the required powder throughput.

五、易損件說明 Description of wearing parts 脈沖閥為易損件屬于正常消耗品,保修期為一年或 100 萬次。如用戶需更換脈沖閥可自行購買。

電壓:220VAC Pulse valve for wearing parts belong to normal consumables, warranty period is one year or 1 million times. If the user needs to replace the pulse valve can be purchased. Voltage: 220 vac

六、設(shè)備運(yùn)行維護(hù) Equipment operation and maintenance

6.1 設(shè)備使用安全:非專業(yè)技術(shù)人員禁止維修裝置設(shè)備,謹(jǐn)防觸電;

Safety of equipment use: Non-professional and technical personnel are forbidden to repair the equipment to avoid electric shock;

6.2 嚴(yán)禁將硬質(zhì)物件投入裝置內(nèi)部;

Hard objects are strictly prohibited to be put into the device;

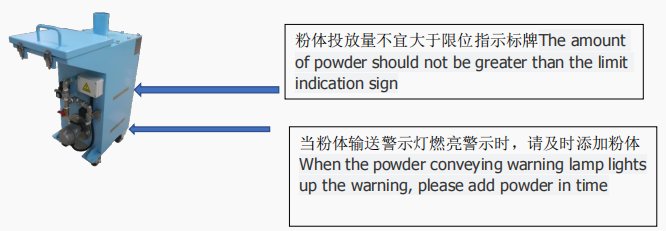

6.3 粉體投放量不宜大于限位指示標(biāo)牌;

The amount of powder should not be greater than the limit indication sign;

6.4 當(dāng)粉體輸送警示燈燃亮警示時(shí),請(qǐng)及時(shí)添加粉體;

When the powder conveying warning lamp lights up the warning, please add the powder in time;

6.5 在正常的運(yùn)轉(zhuǎn)中,粉體輸送裝置蓋板門必須緊扣;

In normal operation, the cover plate door of the powder conveying device must be tightly fastened;

6.6 設(shè)備出現(xiàn)故障或檢修時(shí),必須先關(guān)閉電源,通知有關(guān)技術(shù)人員前來檢修;

When the equipment fails or is repaired, the power must be turned off first and relevant technical personnel must be informed to come for repair;

6.7 在設(shè)備運(yùn)轉(zhuǎn)過程中,如發(fā)現(xiàn)不正常情況時(shí)應(yīng)立即檢查,若是小故障應(yīng)及時(shí)查明原因并設(shè)法消除;

During the operation of the equipment, if any abnormal situation is found, it shall be checked immediately. If any small fault is found, the cause shall be found out in time and it shall be eliminated.

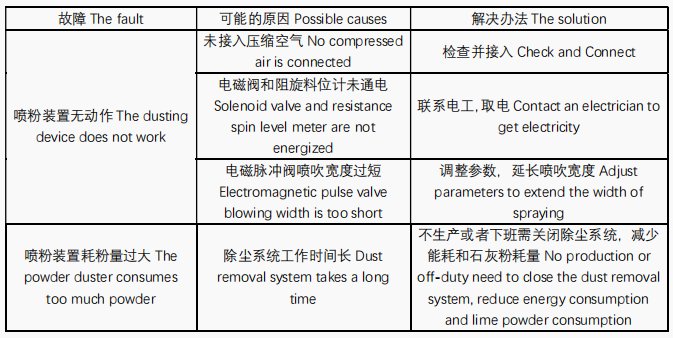

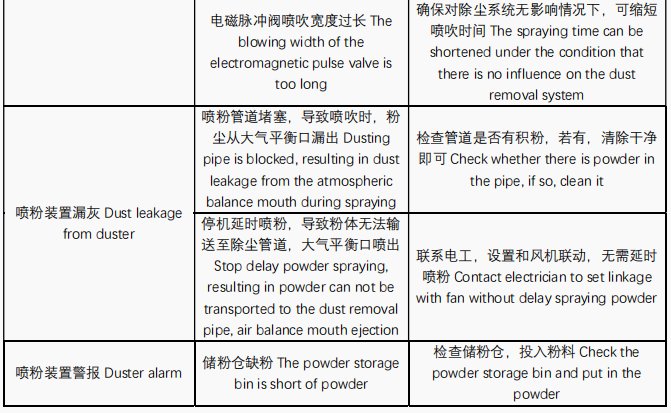

6.8 簡單故障及排除

Simple Faults and Troubleshooting

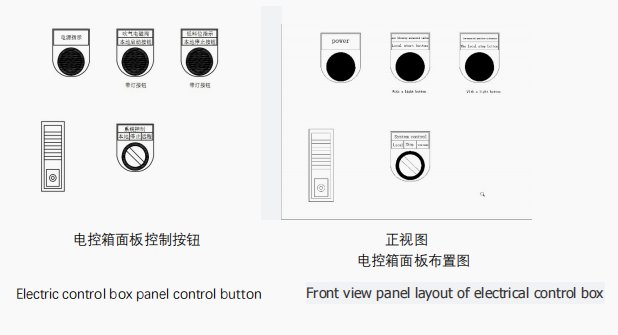

七、噴粉裝置電控箱線路圖

7. Circuit diagram of electric control box of powder spraying device (version should be explained in Both Chinese and English)

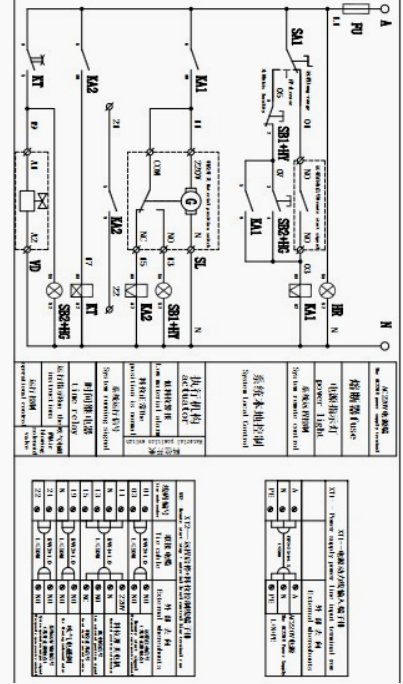

碳酸鈣加料電控箱電路圖

Circuit diagram of calcium carbonate additive electric control box

電氣控制簡要說明 Brief description of the electrical control:

1.操作前必須確認(rèn)電源指示燈燃亮,如需遠(yuǎn)程控制,則將啟動(dòng)常開觸點(diǎn)接入本電控箱。

1. Before operation, confirm that the power indicator is burning.

If remote control is required, the normally open contact will be connected to the

electric control box.

2.料位開關(guān)的低料位報(bào)警燈燃亮后,吹氣電磁閥的運(yùn)行被停止,同時(shí)切斷聯(lián)動(dòng)的系統(tǒng)運(yùn)行

輸出信號(hào)。

2. After the low material level alarm lamp of the material level switch is lit on,

the operation of the blowing solenoid valve is stopped, and the operation

output signal of the linkage system is cut off.

3.吹氣電磁閥運(yùn)行的前提條件是料位開關(guān)處于正常位置。電磁閥的工作模式為間歇循環(huán)方式,

工作時(shí)間和間 歇時(shí)間均可調(diào)整。

3. The prerequisite for the blowing solenoid valve operation is that the material level

switch is in the normal position.The working mode of the solenoid valve is the

intermittent circulation mode, and both the working time and the intermittent time can

be adjusted.

4.本地模式下,啟動(dòng)按鈕和停止按鈕控制料位器和電磁閥的運(yùn)行狀態(tài);遠(yuǎn)程模式下,

由遠(yuǎn)程無源信號(hào)料位開 關(guān)和電磁閥的運(yùn)行狀態(tài)。

4. In local mode, the start and stop buttons control the operating status of the

material holder and the solenoid valve, and those operated by the remote

passive signal in remote mode.