粉體行業(yè)在線展覽

粉體行業(yè)在線展覽

PG雙輥破

面議

PG雙輥破

3405

廣泛使用在水泥, 化工, 電力, 礦山, 冶金, 建材, 耐火材料, 煤礦等各個(gè)領(lǐng)域

廣泛使用在水泥, 化工, 電力, 礦山, 冶金, 建材, 耐火材料, 煤礦等各個(gè)領(lǐng)域

對(duì)輥式破碎機(jī)是破碎設(shè)備的一種, 因結(jié)構(gòu)簡單, 方便維護(hù), 性能穩(wěn)定,能耗低, 經(jīng)久耐用而廣泛使用在水泥, 化工, 電力, 礦山, 冶金, 建材, 耐火材料, 煤礦等各個(gè)領(lǐng)域。Double-roll crusher is one kind of crushing equipment, It has feature of simple structure, convenient maintenance, stable performance, low power consumption, durable and widely used in many areas such as cement, chemical,electric power, mining, metallurgical, building materials, refractory,coal, etc.

1.對(duì)輥破碎機(jī)設(shè)計(jì)合理, 機(jī)構(gòu)簡單, 占空間小, 操作方便Double-roll crusher reasonable design, simple structure, small space occupation, convenient operation.

2.本機(jī)采用了**的機(jī)械結(jié)構(gòu)設(shè)計(jì)和合理的動(dòng)力匹配, 從而很大降低了電能的損耗,比其它規(guī)格破碎機(jī)節(jié)能30%左右。Adopts the optimal mechanical structure design and reasonable power matching, thereby greatly reducing the power loss, about 30% energy saving than other crushers.

3.內(nèi)部裝有防塵板,密封性能好,避免了破碎后的細(xì)小物料的揚(yáng)濺,粉塵少,工作噪聲低,工作環(huán)境有較大的改善。Equipped with dust-proof plate, good sealing performance, avoiding the broken tiny splash of materials, little dust, low noise, use a good environment

4. 磨料輥體重新進(jìn)行優(yōu)化設(shè)計(jì),設(shè)備使用終身不需要換磨機(jī)輥體,而舊型對(duì)輥機(jī)使用一年就需拆開大修,更換輥體。Abrasive roller re optimize design, does not need to change the roller lifelong, while the old roller crusher use for one year would need to open repair, replace the roller.

5. 本機(jī)磨輥上裝有可更換耐磨襯板,耐磨襯板采用國內(nèi)先進(jìn)耐磨材料,具有使用壽命長,不易損壞,方便維修等優(yōu)點(diǎn)。連續(xù)使用壽命可達(dá)一年以上,磨損嚴(yán)重時(shí),移開機(jī)蓋即可更換。維修量小,成本低。Equipped with a replaceable abrasion resistant lining plate, the wear-resistant liner using the domestic advanced wear-resistant materials, has the advantages of long service life, not easy to damage, convenient repair etc.. The continuous service life of up to one year or more, wear serious, remove the cover can be replaced. A small amount of maintenance, low cost.

6. 本機(jī)裝有安全防護(hù)裝置,當(dāng)有意外金屬鐵件進(jìn)入破碎腔后,防護(hù)裝置動(dòng)作,鐵件漏出設(shè)備正常運(yùn)轉(zhuǎn)。Equipped with safety protection device, when have unexpected metal iron into the crushing chamber, the protection device action, iron leakage equipment normal operation

7. 本機(jī)磨料輥體輥縫在1mm~20mm間任意可調(diào),根據(jù)破碎粒度的要求調(diào)好輥縫后,破碎粒度能得到可靠控制,全部以理想粒度由破碎腔下方排出。the abrasive roller roll gap arbitrary adjustable in between 1mm ~ 20mm,according to the requirements of the particle size adjust the roll gap, crushing size can be get reliable controlled, all final products in an ideal size discharged from the bottom of crusher chamber.

8. 結(jié)構(gòu)簡單合理,運(yùn)行成本低,運(yùn)轉(zhuǎn)平穩(wěn),高效節(jié)能,破碎效率高,破碎比大。Simple and reasonable structure, low running cost, stable running, high- efficiency and energy saving, high crushing efficiency,big crushing ratio.

9. 本機(jī)是低轉(zhuǎn)速高壓力對(duì)輥擠壓的工作原理。物料由破碎機(jī)上部垂直落入破碎腔里,由兩輥之間產(chǎn)生的強(qiáng)大壓力擠壓破碎下,物料大部分已經(jīng)成為細(xì)小顆粒,剩余小部分顆粒狀物料的內(nèi)部已經(jīng)產(chǎn)生大量裂紋。在進(jìn)一步粉粹過程中,可較大地降低粉磨能耗, 提高產(chǎn)量。the roller crusher is low speed high pressure roll extrusion working principle. Materials vertical falling into the crushing chamber from the upper crusher, was extruded and broken by strong pressure generated by the two roll, most of materials has become small particles, the remaining small particle materials inside has generated a large numbers of cracks. In the course of further crushing process, can greatly reduce the grinding energy consumption and improve production.

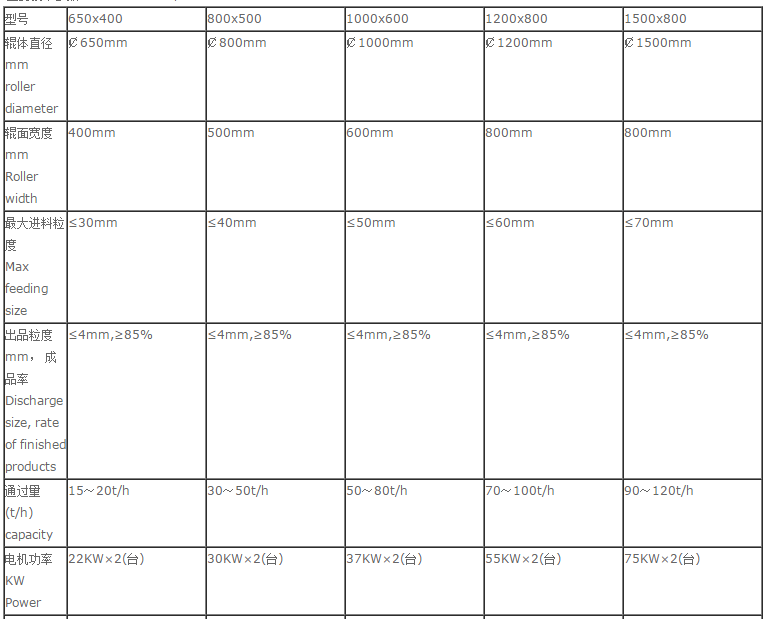

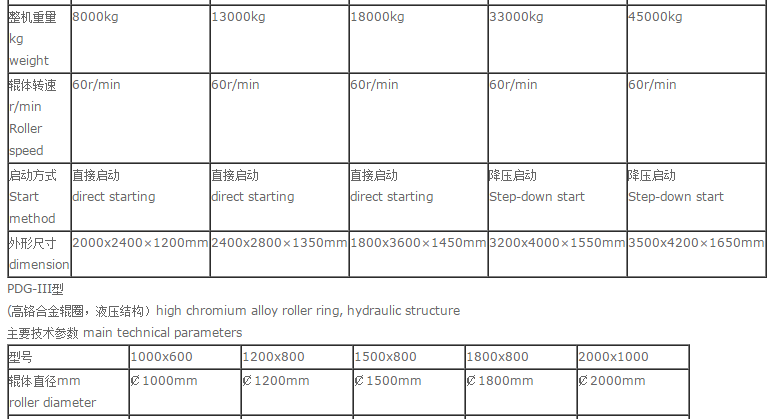

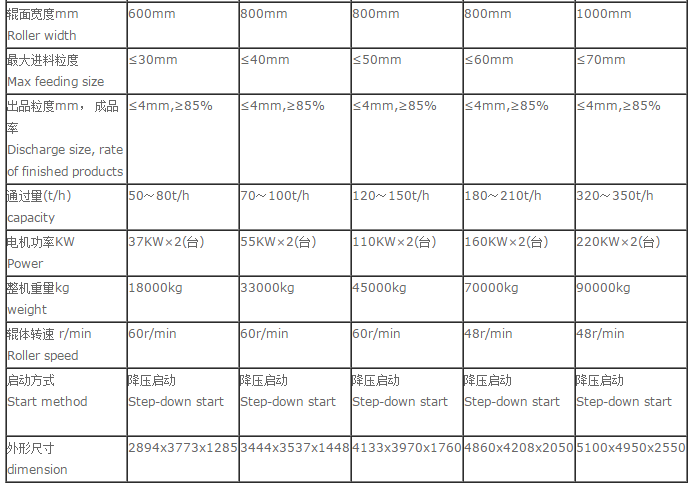

PDG-II型

(高鉻合金輥圈,彈簧結(jié)構(gòu))high chromium alloy roller ring, spring structure

主要技術(shù)參數(shù) main technical parameters